GLAND PACKING

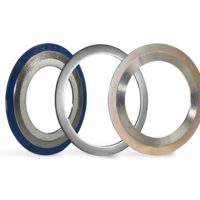

Category GASKETS

Gland packing is a material used in industrial applications to prevent leaks in pumps, valves, and other rotating or reciprocating equipment. It’s placed around a shaft or stem to create a seal between the moving part and the stationary housing. Below are short descriptions of common types of gland packing:

- Graphite Packing: High-temperature, chemically resistant material, commonly used in applications with high-pressure steam or aggressive chemicals.

- PTFE (Teflon) Packing: Known for excellent chemical resistance and low friction, ideal for use in pumps and valves handling corrosive fluids.

- Aramid (Kevlar) Packing: Durable and strong, often used for pumps or valves with abrasive slurries and high mechanical wear.

- Braided Packing: Made from multiple fibers braided together, providing good sealing performance for moderate-pressure and temperature applications.

- Asbestos-Free Packing: A replacement for asbestos packing, offering similar performance without the health hazards, typically used in pumps and valves.

- Carbon Fiber Packing: Often used for high-temperature and high-pressure environments, particularly where chemical resistance and wear resistance are needed.

- Rubber or Elastomer Packing: Provides a flexible and durable seal, typically used for sealing water or mild chemicals at lower temperatures.